how to measure thickness of metal|base metal thickness chart : retailer In the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See more WEBKalamba published Miami Bonus Wheel on March 10, 2020, which is a Medium-high variance, 97.72 % RTP video slot machine. There are 10 fixed paylines and the top .

{plog:ftitle_list}

webNSFW. CATARINA PAOLINO ONLYFANS GRATIS NO GRUPO ABAIXO, LINK ATUALIZADO. 5 0. Share. u/Chemical-Carpet1846. • 1 mo. ago. NSFW. CATARINA .

Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. See moreIn Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See moreIn the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See moreThere are two ways to measure sheet metal: using a measuring tape (which is less precise) and a gauge wheel (more typically used in the industry). See more

Yes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more The chart below can be used to determine the equivalent sheet thickness, in inches . One of the most accurate ways to measure the thickness of thin sheet metal is by using an ultrasonic thickness gauge. This method involves sending high-frequency sound . If you want to find out what gauge your sheet metal is, measure its thickness using a regular tape measure. Then, using a sheet metal gauge chart, you can match that .

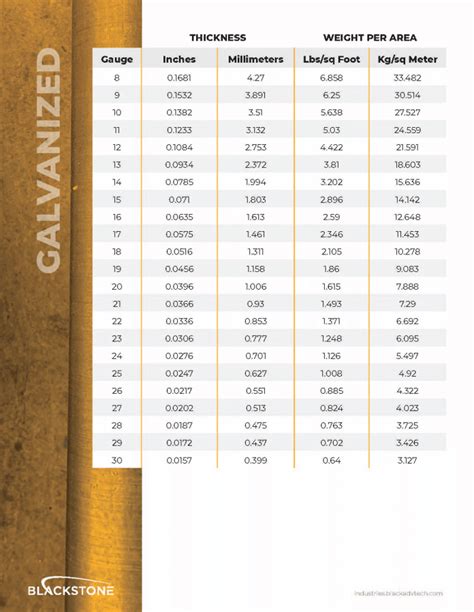

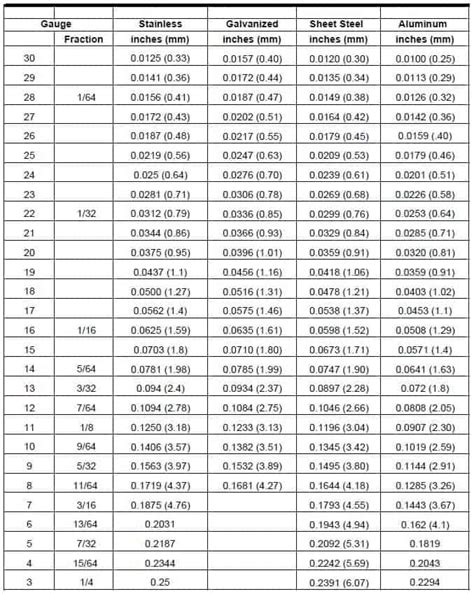

When you need to know the thickness of your metal, a steel gauge chart is your guide. The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value. There are a few different gauge standards, including the Manufacturers’ Standard Gauge, which measures the thickness of regular, galvanized, and stainless steel. Meanwhile, .Decimal measurements offer a more precise and universally interpretable standard for comparing metal thicknesses. However, not all materials are available in decimal measurements, necessitating conversions and careful . Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used .

sheet metal size chart

A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher the gauge number, the thinner the sheet.

STK: A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand Thickness should not be confused with the overall height or depth of . Accurately measuring the thickness of expanded metal is vital to ensure that you choose the appropriate materials for your project. There are several methods to measure the thickness of expanded metal sheets, .

The sheet metal gauge system helps determine the thickness or diameter of different materials, such as metal and wire, based on their weight. Gauge is sometimes called “gage,” often denoted by a number followed by . Measure the thickness of the entire stack with a ruler. Set a ruler against the edge of the stack. Press it down firmly against the table. . on one end. If you’re using a digital model, it will also have a display situated on the ruler portion. Look for a metal wheel attached to the bottom edge of the scale. Rotate the wheel to close the . Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure. Gauges are used to measure the material thickness of a sheet of metal. . Keeping a gauge conversion chart nearby is an easy way to determine the actual thickness of a sheet of metal in inches or millimeters. For example, a 14 gauge stainless steel is .07812 inches thick. The gauge number 14 holds no relevance to the actual measurements.

sheet gauge to mm chart

When reviewing thickness measurement methods, factors to consider include target material, type of measurement and more. Your Product Inquiry List; CONTACT US: 503-210-5733; . but some smaller mills still rely on hand-held micrometers to gauge metal thickness. AR200 laser measurement sensors are ideal for measuring steel strip thickness to .

It is a coincidence that the measuring device is roughly the size of the screw head in millimeters. A 6-gauge screw has a head that is almost 6 mm wide. The correlation between diameter (metric in mm), thickness (imperial) and head size is complicated. Nowhere can you find information that guarantees you can calculate this effectively.Ultrasonic thickness gauging is a widely used nondestructive technique for measuring the thickness of a material from one side. Just about anything made out of metal, plastic, composite, ceramic, glass, fiberglass, or rubber can be measured. This tutorial provides a basic introduction to the theory and practice of ultrasonic thickness gauging .

dye paint test

Screw gauge is an instrument used to accurately measure the thickness of a sheet of metal. It comprises a U-shaped frame fitted to a screwed spindle which is attached to a thimble. A scale graduated in mm is engraved parallel to the axis of the thimble. This is known as the pitch scale. The head of the screw consists of a rachet that avoids .They are ideal for the non-destructive measurement of powder coating thickness on metal substrates. Various models of the . The normal standard used in powder thickness measurement is the mil, where 1 mil is equal to a thousandth of an inch (1/1000”). So if the manufacturer’s specified thickness is 2 to 5 mils, the final cured thickness .

Measure the width of a thread in fractions of an inch to get the diameter. Use a ruler or measuring tape to measure from one side of a thread to the other using the nearest fraction of an inch. This diameter for screws in the imperial system is represented by either a gauge number or in fractions of an inch.Volume. Volume is the measure of the amount of space occupied by an object. The standard SI unit of volume is defined by the base unit of length (Figure \(\PageIndex{3}\)). The standard volume is a cubic meter (m 3), a cube with an edge length of exactly one meter.To dispense a cubic meter of water, we could build a cubic box with edge lengths of exactly one meter. Gauge numbers inversely correlate with sheet metal thickness: as the gauge number increases, the metal thickness decreases. For instance, 8-gauge sheet metal is substantially thicker than 16-gauge. . The concept of “gauge” as a thickness measure emerged during the American Industrial Revolution, driven by wire manufacturers’ need to .

The galvanize coating is applied by the sheet metal supplier either by hot-dip galvanizing or by electrogalvanizing. If the zinc coating thickness were uniform, the thickness of the subsequently applied paint coating could be . Thickness dramatically affects the functionality of coatings. Accordingly, the techniques in use to determine the thickness are of utmost importance for coatings research and technology. In this review, we analyse .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

metric steel plate thickness chart

In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is typically .This average value is called the “base metal reading” or “BMR”. Measure the zinc thickness at the number of spots required by the relevant procedure or standard. Subtract the base metal reading (BMR) from the gage reading to obtain the galvanizing thickness. When utilizing an electronic coating thickness gauge, perform the following steps:

A gauge is a traditional, non-linear measurement. The most commonly used sheet metal sizes range from 30 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness, and show both the gauge number as well as the thickness of the metal in thousandths of an inch. Gauge is a measurement of the thickness of a metal roofing panel. There are a variety of roofing panels that can be used to cover roofs. Manufacturers in the United States use gauge to express the thickness of metal roof panels. Roof panels vary in thickness from 22 gauge to 29 gauge. The smaller the number, the thicker the panel. Here are some common problems and ways to measure coating thickness. Advertisement The Voice of the Finishing Industry Since 1936 . In the metal finishing industry, the thickness of a coating can dictate the functionality, appearance and cost of a final product. Coating thicknesses are typically found in the range from 0.1 to 85+ microns .When selecting sensors to measure thickness or width, the first step is to choose a method. The target's material, color, and location will all play factors in which option is the best fit for your application. . Paste thickness measurement after metal masking. More details. NEW. Reflective. Film coating thickness measurement in explosion .

metal thickness gauge chart

brass sheet metal thickness chart

The magnetic thickness measurements are also non-destructive and can be used to take many readings on many articles very quickly. Details on all four methods can be found in ASTM A123, but this article only addresses the use of the magnetic thickness gages. Measuring Galvanizing Thickness Using Magnetic Gages On the surface, thickness seems like an easy measurement to take, as dimensional measurements go. You have two big, flat, parallel planes on which to plant your gage. For hard materials, like metal sheet, you can use three of the four measuring capabilities of a slide caliper. A micrometer does very nicely, too, if you have the time and need the accuracy.

How to Quickly Measure Sheet Metal’s Thickness. When it comes to measuring sheet metal thickness, there are several methods at your disposal. However, some techniques are more accurate and reliable than others. Option 1: Using Calipers. Calipers are an accurate measuring tool used to measure the thickness of a sheet of metal. Solution 1: Measuring Sheet Metal Thickness With Tape. There are three simple steps required in this, and they include: Step 1. Use the millimeter hash marks on your tape to find the thickness of sheet metal. Remember that there are two different measurements on your tape, namely the cm and mm. Using the former will not provide the accurate .

base metal thickness chart

WEB20 de jan. de 2024 · Horário: 22h15 (de Brasília) Local: Levi's Stadium, Santa Clara. Onde assistir: ESPN, Star+ e NFL Game Pass. Confusão San Francisco 49ers x Green Bay .

how to measure thickness of metal|base metal thickness chart